Semi Truck Axle Seals: What You Need to Know

Semi truck axle seals play a crucial role in keeping commercial vehicles running smoothly on the road. These small but mighty components protect vital axle components from contamination while keeping lubricants where they belong. At Our Auto City, we understand that proper maintenance of these seals can mean the difference between a profitable haul and costly roadside repairs.

When axle seals fail, the consequences can be severe. Leaked lubricants create safety hazards on highways while exposing expensive axle components to dirt and moisture. Additionally, understanding how semi truck axles work together with their sealing systems helps fleet managers make informed maintenance decisions.

However, many truck operators don’t fully grasp the importance of these components until problems arise. Therefore, this comprehensive guide will explore everything you need to know about semi truck axle seals, from their basic function to maintenance best practices.

What Are Semi Truck Axle Seals?

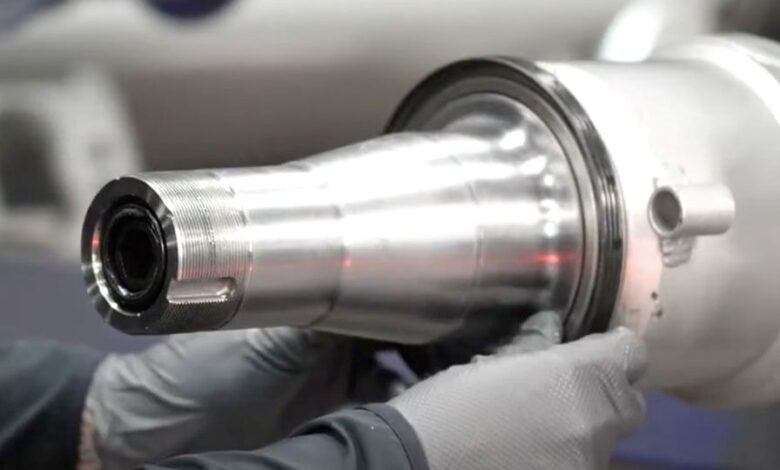

Axle seals are specialized gaskets designed to prevent lubricant leakage from axle housings. These rubber or synthetic components create a tight barrier between rotating shafts and stationary housings. Moreover, they keep contaminants like dirt, water, and road salt from entering critical axle components.

Semi trucks typically use several types of seals throughout their axle assemblies. The most common include wheel seals, pinion seals, and differential cover seals. Each serves a specific purpose in maintaining proper lubrication and protection.

Furthermore, modern axle seals incorporate advanced materials that withstand extreme temperatures and pressures. These improvements have significantly extended seal life compared to older designs.

Types of Axle Seals in Semi Trucks

Wheel End Seals

Wheel end seals protect the space between the axle shaft and wheel hub. These seals prevent gear oil from leaking onto brake components while keeping water and debris out of the hub assembly. Additionally, they maintain proper lubrication for wheel bearings.

Pinion Seals

Located where the drive shaft enters the differential, pinion seals prevent gear oil from leaking along the input shaft. These seals endure constant rotation and significant torque loads. Therefore, they require high-quality materials and precise installation.

Differential Cover Seals

These large seals create a barrier between the differential housing and its removable cover. They allow technicians to service differential components while maintaining a leak-proof connection when properly installed.

Signs of Failing Axle Seals

Recognizing seal failure early can prevent major repairs and safety issues. However, some symptoms may be subtle initially before becoming more obvious.

Visible oil leaks represent the most common sign of seal failure. Fresh oil appears wet and dark, while older leaks show as dried residue around seal locations. Additionally, oil puddles beneath parked trucks indicate active leakage.

Strange noises from axle assemblies may signal seal-related problems. Grinding or whining sounds often indicate that contaminants have entered bearing assemblies due to seal failure. Furthermore, these noises typically worsen under load or during turns.

Reduced fuel economy sometimes accompanies seal problems. Leaked lubricants reduce efficiency in axle components, forcing the engine to work harder. Moreover, contaminated lubricants lose their protective properties more quickly.

Causes of Axle Seal Failure

Understanding why seals fail helps prevent future problems and extends component life. Several factors contribute to premature seal failure in semi truck applications.

Age and wear represent natural causes of seal deterioration. Rubber compounds gradually lose flexibility over time, especially when exposed to temperature extremes. Additionally, constant flexing during operation eventually creates tiny cracks that allow leakage.

Improper installation ranks among the leading causes of premature seal failure. Seals installed crooked or with damaged surfaces cannot maintain proper sealing contact. Furthermore, using incorrect installation tools can damage delicate seal lips during assembly.

Contamination accelerates seal wear significantly. Dirt and debris act like grinding compounds, wearing away seal materials. Moreover, chemical contamination from improper lubricants can cause seal swelling or shrinkage.

According to Commercial Carrier Journal, improper maintenance practices contribute to approximately 40% of axle-related failures in commercial vehicles.

Maintenance Best Practices

Regular inspection schedules help identify potential seal problems before they cause major issues. However, inspections must be thorough and systematic to be effective.

Visual inspections should occur during routine pre-trip and post-trip checks. Look for fresh oil stains, wet spots around seal locations, and accumulations of road dirt mixed with oil. Additionally, check for unusual odors that might indicate overheated lubricants.

Proper cleaning around seal areas prevents contamination buildup. Use appropriate solvents to remove road grime without damaging seal materials. Furthermore, clean areas allow better visibility for spotting early signs of leakage.

Lubricant quality directly affects seal longevity. Use only manufacturer-specified oils and change them according to recommended intervals. Moreover, contaminated lubricants should be replaced immediately regardless of service intervals.

Replacement Procedures

Professional seal replacement requires proper tools and techniques. However, understanding the basic process helps fleet managers communicate effectively with service technicians.

Preparation involves thoroughly cleaning the work area and gathering appropriate tools. Remove wheels and brake components to access seal locations. Additionally, drain lubricants from affected assemblies before beginning seal removal.

Careful removal prevents damage to expensive housing components. Use appropriate pullers rather than prying tools that might gouge sealing surfaces. Furthermore, inspect removed seals for wear patterns that indicate underlying problems.

Installation requires attention to detail and proper technique. Clean all sealing surfaces and check for damage or corrosion. Moreover, apply recommended lubricants to seal lips before installation to prevent initial wear.

Cost Considerations

Axle seal replacement costs vary depending on seal type, truck configuration, and labor rates. However, the expense of replacement pales compared to major axle repairs or accident costs from oil spills.

Individual seal costs typically range from $20 to $100, depending on size and quality. Labor charges for replacement vary by location and complexity but generally require 2-4 hours per seal. Additionally, associated fluid and filter changes increase total service costs.

Preventive replacement during scheduled maintenance reduces overall costs compared to emergency roadside repairs. Furthermore, group replacements often provide labor savings when multiple seals need attention.

Environmental Impact

Failed axle seals create environmental hazards through lubricant contamination. Leaked oils can contaminate soil and groundwater while creating slippery road conditions. Therefore, prompt attention to seal problems protects both the environment and public safety.

Many states impose strict penalties for vehicles that leak fluids on roadways. Additionally, environmental cleanup costs for significant spills can reach thousands of dollars beyond basic repair expenses.

Technology Advances

Modern seal technology incorporates improved materials and designs that extend service life. Advanced synthetic rubbers resist temperature extremes and chemical attack better than traditional materials. Moreover, enhanced lip designs provide better sealing contact while reducing friction.

Some manufacturers now offer seals with integrated sensors that monitor seal condition. These smart seals can alert operators to developing problems before failure occurs. Furthermore, predictive maintenance programs use this data to optimize replacement schedules.

Conclusion

Semi truck axle seals may seem like minor components, but their proper function is essential for safe and economical vehicle operation. Regular inspection and maintenance prevent most seal-related problems while protecting expensive axle components from damage. Additionally, understanding the signs of seal failure helps operators address issues before they become costly emergencies.

Proper seal maintenance requires attention to detail and quality replacement parts. However, the investment in good seals and professional installation pays dividends through reduced downtime and repair costs. Furthermore, well-maintained seals contribute to environmental protection and regulatory compliance.

By following manufacturer recommendations and staying alert to seal condition, fleet operators can maximize axle component life while minimizing unexpected failures. Therefore, make axle seal inspection and maintenance a priority in your preventive maintenance program.

Frequently Asked Questions

Q: How often should semi truck axle seals be replaced? A: Axle seals typically last 300,000-500,000 miles under normal conditions. However, severe operating conditions may require more frequent replacement. Regular inspections help determine actual replacement needs based on seal condition rather than mileage alone.

Q: Can I drive with a leaking axle seal? A: Driving with leaking seals is not recommended and may be illegal in many jurisdictions. Leaked oil creates road hazards and can lead to expensive axle damage. Additionally, continued operation may result in complete seal failure and costly emergency repairs.

Q: What causes axle seals to fail prematurely? A: Common causes include improper installation, contaminated lubricants, extreme operating conditions, and normal wear. Poor maintenance practices and using incorrect lubricant types also contribute to premature failure. Regular inspections help identify contributing factors early.

Q: How much does axle seal replacement cost? A: Replacement costs vary by seal type and location, typically ranging from $150-$400 per seal including labor. Emergency roadside repairs cost significantly more than scheduled maintenance. Group replacements during routine service often provide cost savings.

Q: Are there different quality levels of axle seals available? A: Yes, seals range from basic replacement parts to premium designs with enhanced materials and features. OEM seals typically offer the best fit and longevity, while aftermarket options provide various price points. Choose seals appropriate for your operating conditions and maintenance schedule.

Read More:

Amped Autonomy: The Role of Car Batteries in Vehicle Performance